Custom wholesale new design Forged car 3 pieces forged wheels

Product Description

MODEL NO:R-19

| Size | 17/18/19/20/21/22/23/24 inch | Material | A356.2 |

|---|---|---|---|

| PCD | Customized | MOQ | 4PCS |

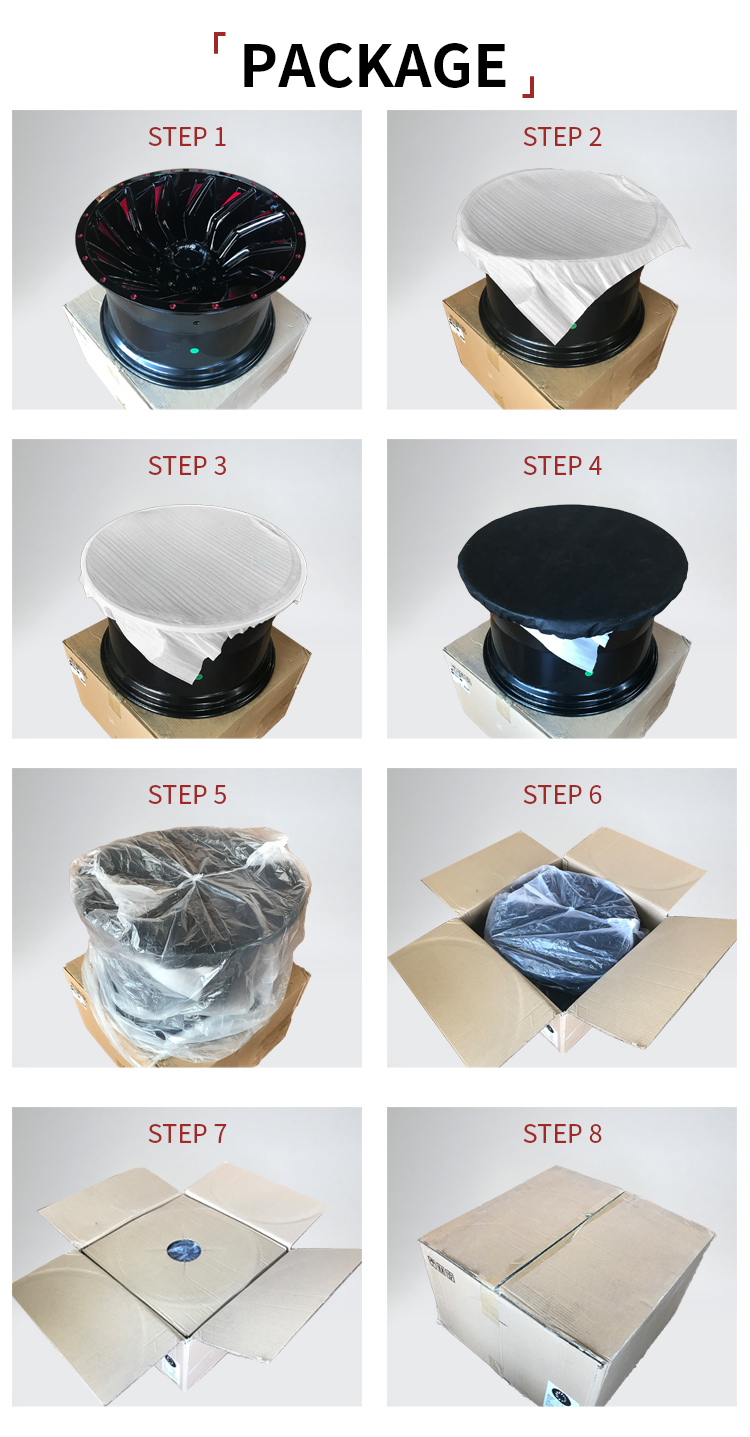

| Standard Carton | Brown Carton/White Carton | Warranty | 3 Years |

Production process

PACKAGE

Our exhibition

Special Service

1. We provide timely per-sale and after-sale service: Before the sample/mass production order placed, all details will be checked and confirmed with customers; We can accept sample order for testing first. Also we have a free sample policy if you place an order to us

2. We provide LOGO customizing (Milled Letters and Word) on wheels;

3. Center caps and Carton LOGO customizing;

4. Wheel's finishing can be your requested.

5. We can do forged, Flow forming and Lower pressure

FAQ

1.Q: How about quality guarantee of your wheels?

A:1) Material Purchase Control Our Material are imported from Malaysia, Thailand ect. Those country specializing in better rubber.

2) Advanced production equipment, including German Krupp mixer, Netherlands VMI tire building machine.

3) all semi-finished tires are inspected 100%, qualified rate is almost 100%. This is seldom in China.

4)There are 5 times inspection for each tyre, including appearance test,X-ray test, dynamic test and so on.

2. Q: Terms of payment

FOB,30%TT deposit, 70% balance before shipping

C&F, 30% TT deposit, the balance should be paid against copy of B/L within 10 days.

By irrevocable LC at sight.

Tip

What is the difference between forged and cast wheels?

Forged wheels are made from a solid block of aluminum, which is heated to high temperatures and then pressed through massive presses to shape it. Afterwards, the design is machined into the final product wheel.

The result of the forging process creates wheels that are stronger than cast wheels, and they are also lighter than cast wheels.

Cast wheels, by contrast, are formed by pouring liquid aluminum or steel into a mold shaped like the wheel. After the liquid has cooled, the wheel is machined according to the design and final shape.

In general, the casting process is much cheaper than the process of making forged wheels, which is probably why most factory vehicles will have cast wheels, while forged wheels are usually purchased by car enthusiasts or aftermarket for racing purposes.