Alloy wheels rims 20X8 20X10,4×4 rines wheels candy red 16×8 17×9 pcd 6×139.7 5×150 offroad wheels

Product Description

| Size | 17 20 inch | Material | A356.2 |

|---|---|---|---|

| PCD | 6X139.7/6X135 | MOQ | 80PCS |

| Standard Carton | Brown Carton/White Carton | Warranty | 3 Years |

Production process

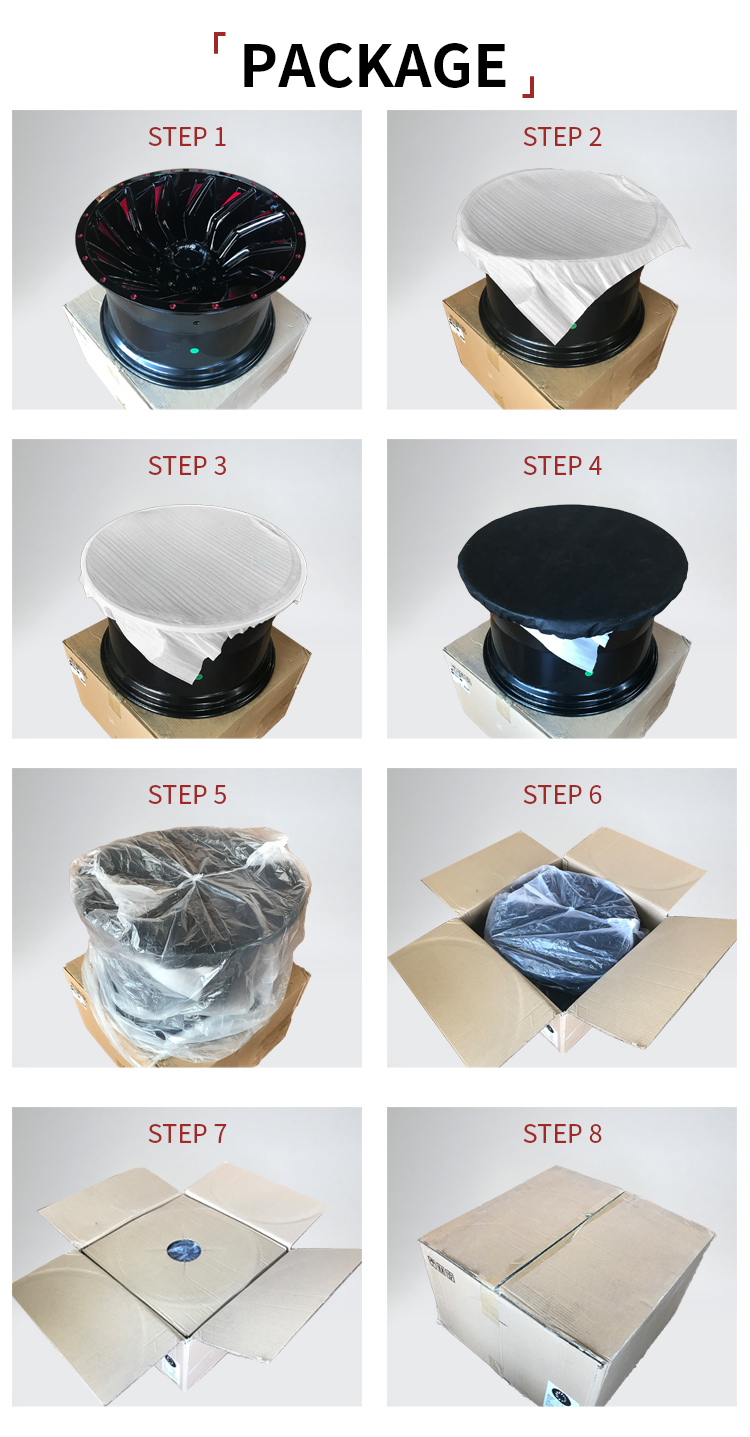

PACKAGE

Our exhibition

Special Service

1. We provide timely per-sale and after-sale service: Before the sample/mass production order placed, all details will be checked and confirmed with customers; We can accept sample order for testing first. Also we have a free sample policy if you place an order to us

2. We provide LOGO customizing (Milled Letters and Word) on wheels;

3. Center caps and Carton LOGO customizing;

4. Wheel's finishing can be your requested.

5. We can do forged, Flow forming and Lower pressure

FAQ

1.Q: How about quality guarantee of your wheels?

A:1) Material Purchase Control Our Material are imported from Malaysia, Thailand ect. Those country specializing in better rubber.

2) Advanced production equipment, including German Krupp mixer, Netherlands VMI tire building machine.

3) all semi-finished tires are inspected 100%, qualified rate is almost 100%. This is seldom in China.

4)There are 5 times inspection for each tyre, including appearance test,X-ray test, dynamic test and so on.

2. Q: Terms of payment

FOB,30%TT deposit, 70% balance before shipping

C&F, 30% TT deposit, the balance should be paid against copy of B/L within 10 days.

By irrevocable LC at sight.

Do you kown

Low pressure and gravity casting are two similar casting processes used to manufacture metal parts and components. Each casting method has its own benefits and drawbacks, so it is important to understand the differences between them.

Low pressure casting is a process in which molten metal is injected into a mold at a low pressure, usually less than 10 pounds per square inch. The low pressure results in less force being applied as the molten metal is pushed into the mold, allowing for cleaner, smoother surfaces with fewer surface defects. Low pressure casting also requires less energy than other casting methods, and allows for greater control of the speed and volume of the molten metal being injected into the mold.

Gravity casting, on the other hand, utilizes gravity to fill the mold with the molten metal. This process is done in an open mold, usually with a ceramic core, into which the molten metal is poured. The core holds the shape of the part as the metal cools and solidifies. The downsides to this process are that because it relies entirely on gravity, the molten metal takes more time to fill the mold, and the surface finish of the part may not be as smooth as in low pressure casting.

In summary, both low pressure and gravity casting have their advantages and drawbacks. Gravity casting is a slower process and results in rougher surfaces, while low pressure casting is much faster and produces parts with superior surfaces. Companies should decide which casting process is the best fit based on the desired output and their budget.